laser-cutter-has-a-poor-engraving/cutting-qualityedge!

I believe that many friends who have laser cutting machines will encounter such problems. The quality of cutting products or engraving products made with laser cutter is very poor. Why is the quality of my laser cutting machine so bad? Is there a problem with the quality of my laser cutting machine? Sometimes this may be one of the factors. But today I will explain the reasons for this low quality.

1, the reason that affects the quality of cutting

First, we need to know the measure of cutting quality.

1.Cutting surface roughness Rz

2.Cutting slag size

3.Trimming verticality and slope u

4.Cutting edge rounded size r

6.Flatness F

The related concepts above can be checked online.

Cutting accuracy is the first factor to judge the quality of CNC laser cutting machine. Four factors affecting the cutting accuracy of CNC laser cutting machine:

2, the reason that affects the quality of engraving

If your laser cutter’s engraving quality is very poor, it has the following possibilities:

A.Laser head is loose

Please fasten the laser head as below

B.The focus lens or the reflective mirrors are loose

Please fasten the focus lens and the three reflective mirrors as below

C.The material is loose

Use some magnet or heavy items to fasten the material

D.The machine shakes

Please fasten the four wheels and the foot cup

E.X axis belt loose

Please do these two tests:

Test 1: engrave a 50x50mm square and set the scan mode as X_unilateralism

Test 2: engrave a 50x50mm square and set the scan mode as X_swing

If the engraving edge of test 1 is smooth and test 2 is not, that means the belt is loose.Please fasten the belt as below(① fix the belt; ②adjust the tension of the belt;)

F.Please set the Scan Mode to X-unilateralism

Although the engraving speed is slow, it can improve the engraving effect very well.

Finally, I am very happy that everyone can see this article. There are a lot of deficiencies in the article. I urge everyone to criticize and correct. I hope the article can help everyone.

1, the reason that affects the quality of cutting

First, we need to know the measure of cutting quality.

1.Cutting surface roughness Rz

Rz is one of the basic evaluation parameters for surface roughness that is widely used. Rz is more intuitive, but only reflects the peak-to-valley height of the surface profile being measured.Rz commonly used in the range of 0.1 ~ 25μm.

|

| Different roughness |

2.Cutting slag size

3.Trimming verticality and slope u

4.Cutting edge rounded size r

5.Drag after the stripe n

6.Flatness F

The related concepts above can be checked online.

Cutting accuracy is the first factor to judge the quality of CNC laser cutting machine. Four factors affecting the cutting accuracy of CNC laser cutting machine:

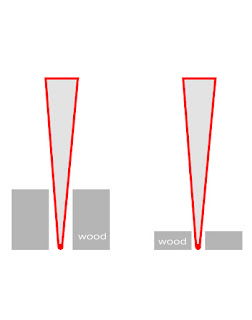

- The size of the laser agglomeration of the laser generator. If the spot is very small after the aggregation, the cutting accuracy is very high, and the gap after the cutting is also very small. This shows that the precision of the laser cutting machine is very high and the quality is very high. However, the beam emitted by the laser is tapered, so the slit is also tapered. Under this condition, the greater the thickness of the workpiece, the lower the precision, so the larger the slit.

The size of the laser condensation - The accuracy of the workbench. If the accuracy of the table is very high, the precision of the cutting is also improved. Therefore, the accuracy of the workbench is also a very important factor in measuring the accuracy of the laser generator.

Laser table - The laser beam condenses into a cone. When cutting, the laser beam is tapered downwards. If the thickness of the workpiece to be cut is very large, the precision of the cutting will be reduced, and the cut gap will be very large.

Crevices cut from different thicknesses of wood - The material to be cut will also affect the accuracy of the laser cutting machine. In the same situation, the precision of cutting stainless steel and cutting aluminum will be very different, the cutting precision of stainless steel will be higher, and the cut surface will be smoother.

Cutting stainless steel

------------------------------------------ split line ----------------------------------------

2, the reason that affects the quality of engraving

If your laser cutter’s engraving quality is very poor, it has the following possibilities:

A.Laser head is loose

Please fasten the laser head as below

|

| Laser head |

B.The focus lens or the reflective mirrors are loose

Please fasten the focus lens and the three reflective mirrors as below

|

| focus lens and reflective mirrors |

Use some magnet or heavy items to fasten the material

|

| fasten the material |

D.The machine shakes

Please fasten the four wheels and the foot cup

|

| fasten the four wheels |

E.X axis belt loose

Please do these two tests:

Test 1: engrave a 50x50mm square and set the scan mode as X_unilateralism

Test 2: engrave a 50x50mm square and set the scan mode as X_swing

|

| two tests |

If the engraving edge of test 1 is smooth and test 2 is not, that means the belt is loose.Please fasten the belt as below(① fix the belt; ②adjust the tension of the belt;)

F.Please set the Scan Mode to X-unilateralism

Although the engraving speed is slow, it can improve the engraving effect very well.

Finally, I am very happy that everyone can see this article. There are a lot of deficiencies in the article. I urge everyone to criticize and correct. I hope the article can help everyone.

Comments

Post a Comment